|

|||||||||||||||||||||||||||||||||||||

| FERRO Process Temperature Control Rings 660~1750℃ | |||||||||||||||||||||||||||||||||||||

| 测温环特性: 很多高温耐火产品在生产过程中需要有效地测量窑炉温度,但多数测量手段和工具在时间和空间上均受到限制。 例如:热电偶并不能测量产品本身的温度,而是产品烧制时的环境温度。热电偶记录在顶端获得的温度,只是空间和时间的一点, 一个热电偶无法决定加热过程;一只热电偶是无法提供窑炉在不同方位加热是否均匀的信息,它只能测辐射热,而不涉及来自窑炉 具的传导热。 FERRO 测温环是一种高精密度的陶瓷温度指示器,它忠实记录了烧制过程中制品所经历的热过程。 FERRO 测温环不仅可以测出辐射热与放射热,还考虑了温度随时间推移所产生的影响。 FERRO 测温环能方便地把受热过程以一个简单的数字来表示--环温度(RT),便于应用在实际工作中。 |

|||||||||||||||||||||||||||||||||||||

| Process Temperature Control Rings Higher quality products and lower costs through improved, reliable firing control Take control of your firing process In the manufacture of ceramic products, few things are as critical as accurate control of the firing process. After all, the results have a direct effect on the quality - and the costs - of the final product. Optimal firing control requires both accurate measurement of the heat treatment - the temperature and its effect over time - together with the ability to control the temperature and the uniformity of its distribution throughout the kiln. Effective temperature measurement is the key to guaranteed product quality. Most conventional temperature measurement techniques are limited both in time and in location. For example, the thermocouples generally used in the ceramic industry do not measure the temperature of the product itself,but that of its vicinity. They are also limited to measuring radiated heat, and take no account of heat transferred from kiln furniture. |

|||||||||||||||||||||||||||||||||||||

广东测温环 |

|||||||||||||||||||||||||||||||||||||

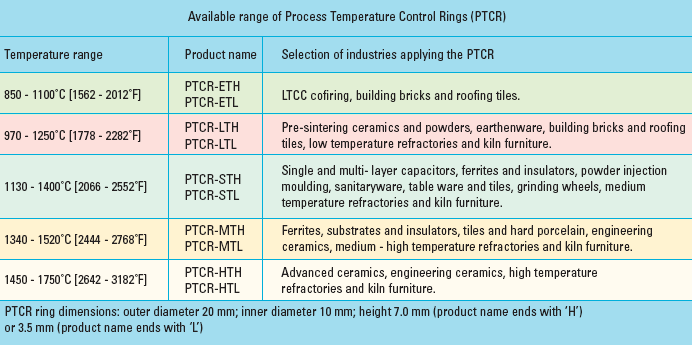

| FERRO Process Temperature Control Rings 陶瓷测温环的型号及应用行业 | |||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||

| FERRO Process Temperature Control Rings 测温环规格 | |||||||||||||||||||||||||||||||||||||

| PTCR测温环尺寸: 外径:20mm, 内径:10mm, 厚度:7.0mm。 PTCR为可靠的高精度产品,*大误差小于3℃。甚至可达1.5℃。 产品包装:15个/小纸盒、600个/大盒。 The multifunctional PTCR concept comprises • improved ceramic PTCR rings • improved, convenient packaging • the PTCR micrometer with numerical or digital read-out • a batch-specific temperature table PTCR: What it is The Process Temperature Control Ring, PTCR,is a highly accurate ceramic temperature indicator which records the true heat treatment received by the fired product. PTCR rings take account of both radiated and transferred heat, as well as the effects of temperature over time. It conveniently allows this recorded heat exposure to be expressed as a single number - ring temperature (RT) - which is practical and easy to work with. PTCR rings can be used in both batch and continuous tunnel kilns; they are used in a range of atmospheres*. Five different PTCRtypes are available - in heights of 3.5 and 7.0mm - covering a range from 850 to 1750°C(1562 to 3182°F). Ring types are identified by color coding and batch and type numberspressed into the ring. Originally PTCR has been developed for inhouse application in critical firing processes for advanced electronic ceramic components. Now, the PTCR brings the benefits of easy,accurate kiln temperature measurement to awide range of industries. PTCR: How it works When exposed to heat in the kiln, the PTCR ring contracts - and continues contracting as the top temperature is maintained over time. The degree of contraction is almost linear over the complete operating range of the PTCR,providing a practical measure of the accumulated heat to which the ring - and the fired products - have been subjected. The amount of contraction - the amount by which the ring diameter has shrunk - is measured with a numerical or digitalmicrometer. This measurement can be converted to 'ring temperature' for ease of comparison and correlation to the firing process. PTCR: Quality you can rely on PTCR is recognized for its accuracy and reliability, and its recently improved technology now offers an unsurpassed accuracy guarantee: a minimum variation of 3°RT. ** This reliability is based on a stringent manufacturing process. PTCR rings are made from a mix of high-grade materials. Their composition is fine-tuned through advanced Design Of Experiments- (DOE) techniques, and the production process itself is controlled by Statistical Process Control. In fact, the entire PTCR manufacturing facilities have been awarded the internationally recognized ISO 9001:2000 and ISO 14001 quality certification.  |

|||||||||||||||||||||||||||||||||||||