|

| FERRO PTCR测温环工作原理及使用方法: |

| 1、FERRO PTCR测温环具有可靠性,测温环几乎可被放置在窑炉的任何位置,炉体内、推板或传输带上 ,在使用前,不必测量温度; 2、FERRO PTCR陶瓷测温环的工作原理是根据其在工作温度范围内的线性收缩,从而给出测温环和烧成品的实际累计热量,对照换算表得出测试温度,烧制结束后,将测温环取走并做记号; 3、FERRO PTCR陶瓷测温环在窑炉中受热时,它就收缩,并在*高温度随保温时间延长而继续收缩。 在其使用温度范围内,收缩率是线性的,这为FERRO陶瓷测温环和被烧制的产品所受到的加热量提供了一种实用的测量方法;收缩量(环直径的减少)可用数字 千分尺测量 ,使用的手持数字千分尺记录每一片测温环的直径, 到0.01mm; 4、参照包装上所附的 环外径与温度对照表、温度校正曲线图(随产品提供),所测出的测温环直径可转换成 等效温度。 注意:为了使用时和方便FERRO测温环 每个温度表都是为该批测温环而特别制定的,所标的生产批号必须与温度 对照表上的保持一致。 |

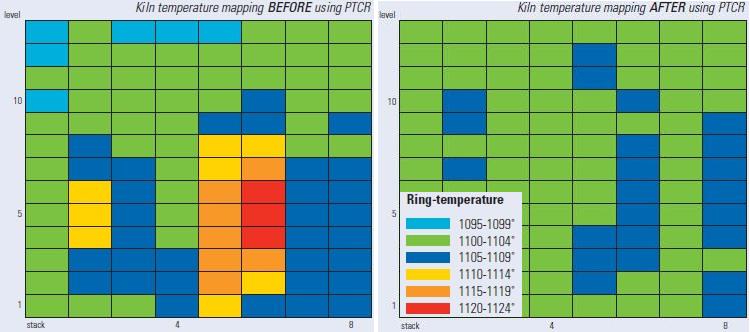

| PTCR in practice: accuracy and convenience Firing process optimization In the process of establishing a standard, the firing process is characterized by 'mapping' the ring temperatures of PTCR rings distributed throughout the kiln. This allows the 'hot' and 'cold spots' to be detected and defined. Using the heat treatment mapping, the firing process can then be optimized by offsetting heat sources or thermocouples as indicated by the variations in ring temperatures. As a rule of thumb, one degree of ring temperaturecorresponds to one degree Celsius. The exact relationship between ring temperature and degrees Celsius is of course dependent upon the specific firing cycle of the kiln. The adjoining illustration shows two heat treatment mappings of the same 15m3 kiln. The first was generated before using thePTCR; the second, after firing process optimization using PTCR rings, resulting in substantial yield improvement. |

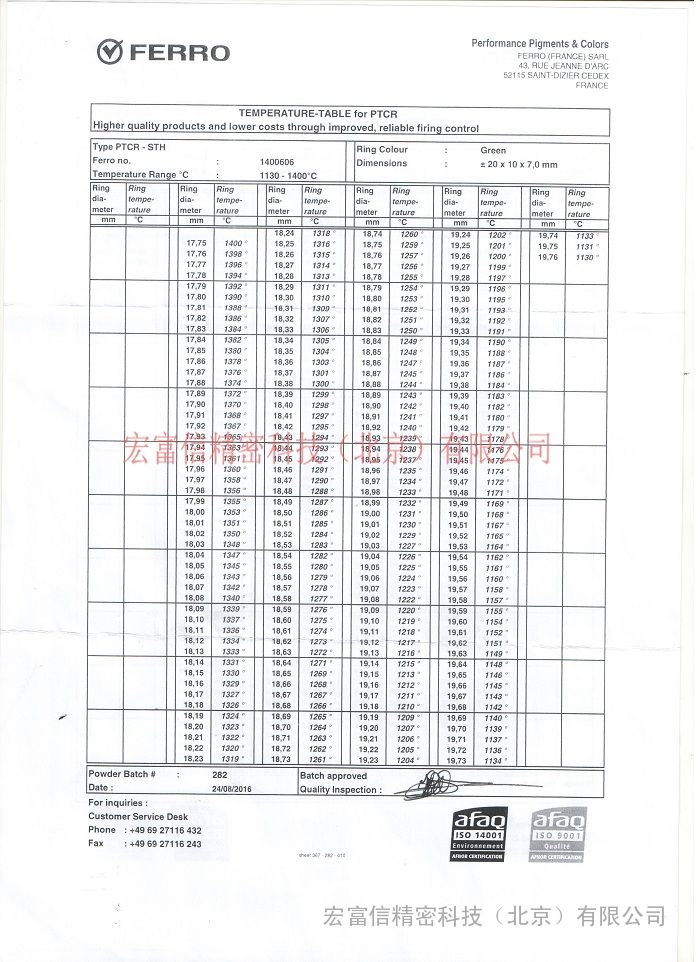

| Firing process control In the course of time - as a result of aging of the heating elements or frequently alternating firing cycles - 'hot' and 'cold spots' maygradually return to the kiln.The PTCR can help here, too. once the firing process has been optimized, PTCR rings can be used regularly to monitor the firing process and to detect these deviations as they gradually arise, before they affect product quality. By comparing the current ring temperatures against the defined standard, the number of degrees of ring temperature by which the firing process must be adjusted can be determined. Using several rings at critical locations in the kiln ensures that an even heat distribution is maintained. Quality control at lower cost Besides the benefits of yield improvement through optimization of the firing process, the PTCR can also help reduce production costs.Simple comparison of ring temperature against a quality standard indicates whether the products are sintered to specification.Expensive, time-consuming conventional quality checks - destruction testing, geometry,density and porosity tests - can be reduced or eliminated. |

|

| 测温环测定窑炉温度分布图: |

| 测温环被广泛应用于连续窑和非连续隧道窑、梭式窑、辊道窑、钟罩窑等等,推荐使用多位放置和多水平放置,这可使您对窑内热分部有个直接地了解。 FERRO PTCR测温环可应用在氧气、氮气、空气、真空和还原等不同烧成气氛中。 |

| 窑炉应用FERRO测温环测量的优点: |

| 1、FERRO测温环使用机动灵活,可简易方便测定炉内三维空间温度分布的任何角落。 2、FERRO测温环安放位置贴近产品实际受热状态,测定烧制品 实际受热情况。 3、FERRO测温环一致性良好,可以保证产品烧成制度的良好重现性,从而提高成品的合格率。 4、使用FERRO测温环可以减少甚至不再需要通过对烧成品的几何形状,密度和多孔性测量或破坏性试验。 从而减少生产过程中的质量控制成本。 5、FERRO测温环陶瓷测温环为可靠的高精度产品,具有公认的性和可靠性,的温差达1.5—3℃。 |

| Method of use Positioning PTCR rings can be placed at almost any location in the kiln, on kiln furniture, trolleys or transports. The use of both multi-location and multi-level positioning is recommended, as this provides the most insight into the heat treatment distribution within the kiln. Measuring The contraction of the PTCR diameter reflects the actual heat treatment at the point where the ring was located in the kiln. The diameter is easily measured using a PTCR micrometer - only a single measurement is required (as shown). PTCR micrometers Numerical (N) and Digital(D) have an integral, ergonomically designed solid base with a ring positioning chuck, which ensures the ring is always correctly positioned in the micrometer. This design not only simplifies the measuring process, but also improves the repeatability and reproducibility of ring temperature measurement. Converting to ring temperature The measured ring diameter is converted to ring temperature using the conversion table enclosed in each packing unit. Each table is specific to the particular batch of rings, for accuracy and convenience.The ring temperature is a practical single number which is useful for comparison purposes - for instance to relate the recorded heat treatment to the firing process and defined standards - so that any required adjustments can be made. It does not necessarily reflect the actual kiln temperature; the PTCR acts as an accumulator, measuring the total heat treatment over time, rather than the maximum temperature attained. Establishing a standard ring temperature In order to make ring temperature comparisons between different firings, a standard ring temperature must be defined. This is done by including PTCR rings in a series of firings, and relating their ring temperatures to the quality of the products produced. The ring temperature which corresponds to products fired to the correct specifications can be used as the standard. |

|

| 用测温环改善窑炉烧成产品质量的案例: |

| 1、测温环在电子陶瓷产品生产中的应用 |

| 不论是电子陶瓷用粉体还是电容器、电阻器、电感器之类的电子陶瓷元器件,对电性能的要求都较高。在配方和生产工艺相对固定的情况下,烧制品的累积热效应是直接影响产品电性能的因素,而热效应主要是烧成温度、保温时间和烧成气氛的综合体现。 不同的烧成温度、保温时间和烧成气氛会烧结出不同性能的产品;同一批产品在相同的保温时间,但放置在炉子的不同部位也可能烧出不同质量的产品。在实际生产中,难以从生产过程中直接判断或选别出良品就投入下道工序的生产,这样生产出来的产品不良率容易处于失控状态。而现有各类窑炉的测温点都相对固定,热电偶的实际探测点的分布也受到限制,不利于掌握产品在烧成中的真实状态。 另外,即使忽略不同材料的热电偶和新旧不同的热电偶在测量温度时产生的温度误差,热电偶也只能测出烧成温度中的辐射热,无法测量出窑具的传导热和具体的保温时间以及实际烧成气氛的综合热效应。这时若在烧制前或烧成中放置几片测温环,不仅可测出炉内的实际温度而提前调整好炉温,而且还能根据出炉后测温环的直径大小、颜色深浅以及形状的变化等,体现出产品烧成的实际热效应。 测温环体积小巧、使用方便,不但对不同窑炉烧结的产品可作横向比较,而且可将测试后的测温环样品和数据留存起来对不同时期烧结的产品作纵向比较,这样对产品质量的追踪提供了真实的历史依据,对产品质量的严格管理更有保障。 |

| 2、利用测温环解决窑炉横向温差偏大的问题 |

| 窑炉横向温差偏大,容易导致窑炉同一行出砖产生色差缺陷,这种色差常常呈逐渐过渡状,一般不易区分开来,窑炉越宽,这种缺陷越明显。其实对于温差问题的解决方法是很多的。而难题在于如何准确知道窑炉内不同位置的温差。试验证明在抛光砖生产中,应尽量控制窑炉烧成带横向温差≤5℃。 常用的测温设备如测温热电偶仅设在窑炉的一侧,对其横向温差不易检测和控制,所以很难做到横向温度的均一。而通过使用测温环,因其体积小巧,可准确测量不同位置的窑温,得到窑炉内温差的值。一方面弥补了热电偶的不足,另一方面又测定了窑炉内三维空间热分布状况。 再通过合理设定各烧咀的风油(气)比例,正确调节其阀门开度,及时补加耐火石棉等,防止窑墙漏风和不良的散热,对于解决温差的问题就容易得多了。 |

| 3、测温环在箱式电炉中的应用 |

| 箱式电炉广泛用于实验室和小件产品的生产,因其投资小,使用灵活而成为烧成设备。由于电子陶瓷和现代精细陶瓷对烧成温度非常敏感,温度偏差3-5℃即可造成产品性能明显差异,所以保证箱式炉内温度的均匀性是十分必要的。实际使用中,因箱式炉发热元件的设置不同,往往是中间温度较均匀,四周温度较不稳定。 一般情况下箱式炉都带有热电偶进行测温,但因热电偶放置空间的局限性,无法测量出炉内各个点的温度,因此对于炉内温差分布情况无法查明。对于烧成品的如何摆放,要进行较多次的试验才能合理,但炉内放置产品的多少或品种发生变化后,温差也会发生变化。因此需要一种简单、方便的手段随时测量出炉内各个角落的温度。 |

| 4、测温环在辊道窑中的应用 |

| 陶瓷制品在辊道窑里烧成,需要在特定的烧成制度下进行,合理的烧成制度是得到良好产品的根本保证。烧成制度包括温度制度、压力制度、气氛制度,其中温度制度*为关键。辊道窑的温度监测主要是依靠沿窑长装在窑顶或窑侧的热电偶所反映的温度数据。 辊道窑一般分为预热带、烧成带和冷却带,其中烧成带温度的检测主要是确定烧成带的*高温度和高温区间长度即制品在高温下停留的时间,烧成带的*高温度是成瓷的*高温度点,它直接影响到产品的生烧与过烧,高温区的长度影响到保温时间的长短,从而也影响到产品的质量。因此控制烧成温度是保证产品质量的关键。有时热电偶所指示的温度达到了产品烧成的温点,但因保温时间的不同,产品也会产生很大的差别,原因在于热电偶只测量其探头所在位置的辐射热,对于产品因保温时间长短、窑具产生的传导热等综合热效应是无法记录的。 测温环可以记录产品在烧成过程中所累积的全部热效应。能提供一种有别于热电偶等设备测量反映的产品烧成情况。是一种更贴近产品,更真实反映产品受热的一种较好的测温工具。 |

| 5、测温环在立式窑烧结电子陶瓷中的应用 |

| 立式窑以其操作简单,温度均匀,烧结的连续性等优点而广泛用于电子陶瓷的烧结。比如:瓷片电容、PTC陶瓷电阻器、氧化锌压敏电阻器以及PZT压电陶瓷等。这些产品烧结温度的准确性要求都较高,若同类产品在烧结过程中温差过大,不但会影响产品的一致性,而且容易导致整批产品的报废。 立式窑的热电偶探头一般布置在炉膛的外侧,其测出的温度不是产品烧结的实际温度,这就要求产品在烧结前不但要知道其理论烧结温度,更应了解炉膛内的实际温度与表头温度的差异,否则依理论温度调整过来的表头温度是难以烧出高质量的产品。此时采用校温环提前校对一下炉膛内的温度,不但可以减少物料的浪费,而且可以节省宝贵的试炉时间。 立式窑的连续性烧结又使得每炉产品在烧结过程中处于不可视状态,为确保产品出炉后的质量,在每批产品的烧结过程中用测温环来监控也就很有必要。考虑到热电偶也与其它的仪器仪表一样在使用一段时间后会老化或精度较低,加热元件本身也是易老化,在电子陶瓷产品烧结中有规律地(比如每天1次)放入测温环,就可监测烧结产品的炉温变动状态。从长远来看,在立式窑中烧结产品使用校温环作为监控手段,可以保证产品的质量和一致性。 |

| 6、测温环在磁性材料中的应用 |

| 镍锌、锰锌钴、钕铁硼等磁性材料的生产和研发过程中,需要对新型材料生产工艺温度(预烧料温度)进行拟定烧成温度;对二次磁性材料产品烧结同样需要准确的窑炉温度,以便稳定磁性产品的电性能指标。窑炉一般是通过热电偶传递窑炉温度,但热电偶因不同的生产商、不同的窑炉、不同的规格等因素,在同一企业内也较难统一测温标准,容易出现研发部门测试的烧成温度与生产部门的实际控温不相符,给生产带来不便。 测温环能准确提供炉膛内部的实际温度效应(即产品的累积热效应),能对磁材产品所需的累积热进行质量跟踪,同时客观记录炉膛内每天的温度变化情况,提供准确的数据信息,作为温度质量跟踪的档案数据,有利于贯彻实施ISO的质量跟踪管理体系,实现内部研发与生产控温标准的统一,降低不同批原料带来烧结温度变化的复杂性。 |

PTCR: a quality product from a quality source Worry-free firing control, day after day Ferro places great emphasis on the quality of PTCR rings - after all, the quality of the rings has a direct impact on the quality of our customers' products! All raw materials used in the powder mix from which the rings are manufactured undergo extensive laboratory testing. The powders are homogenized, and each individual batch is numbered and inspected once more, to guarantee both physical and pressingproperties. A unique batch identifier is pressed into each individual ring, allowing any ring to be traced back to its original powder batch, if necessary. As each batch of powder is released, the ring temperature conversion table is calculated - specifically for that batch. Ferro’s unique approach to temperature tables relieves PTCR users of the need to recalibrate or recalculate standard ring temperatures when introducing rings from a new batch. Since each individual PTCR ring can be relied on to perform as specified in the conversion table, absolute accuracy is always assured. The PTCR's accuracy, reliability and convenience free you from the concerns of firing quality and control - allowing you to concentrate on the quality of your product, not on temperature control. Process Temperature Control Rings: higher quality products and lower costs through improved,reliable firing control |

|

| 测温环使用注意事项 注意:为了使用时和方便,每个温度表都是为该批环而特别制定的。为保证正确使用,请注意FERRO测温环上所标的生产批号必须与温度换算表上的保持一致。 |

| Method of use Correct positioning is essential to allow accurate ring diameter reading in a single measurement. The special PTCR micrometers feature a positioning chuck that assists in placement of the ring, helping ensure that measurement is made correctly - across the middle digits of the ring number. |

| 测温环对照表校正曲线图下载: |